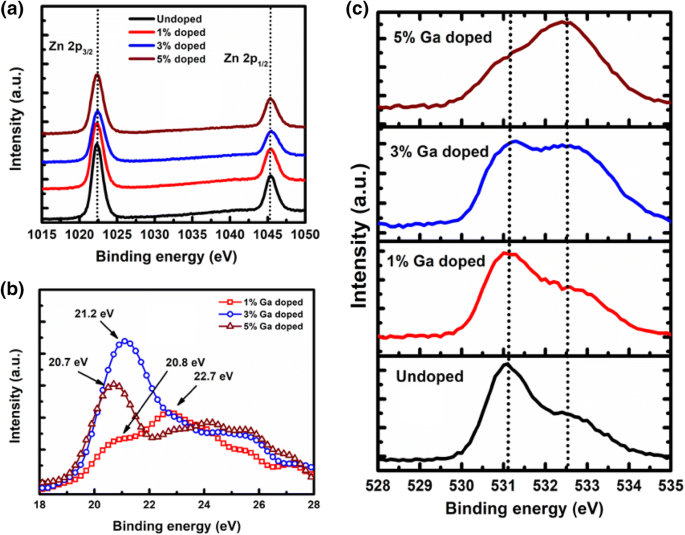

The oxygen plasma treatment was intended to reduce oxygen vacancies, as reactive oxygen plasma diffuses through ZnO nanorod surfaces and traps electrons, as depicted in Fig 1. The ZnO nanorods were treated with oxygen plasma using a RF magnetron sputtering system. Key words: zinc oxide, nanorod, oxygen plasma, lateral force microscopy, nanogenerator, piezoelectric It was confirmed that the elastic modulus of ZnO nanorods increased due to the reduced number of defects originating from oxygen vacancies. Next, the effects of oxygen plasma on the elastic properties of ZnO nanorods were studied using lateral force microscopy. The XPS analysis results showed that oxygen vacancy defects on the ZnO nanorods were decreased by oxygen plasma treatment. From X-ray photoelectron spectroscopy (XPS) measurements, three distinct peaks corresponding to lattice oxygen, oxygen vacancies, and absorbed oxygen on the surface were identified. First of all, the surface roughness of the ZnO nanorods was analyzed using AFM, revealing that it increased due to the etching effect of the oxygen plasma.

In the present work, we observed the effects of oxygen plasma on the elemental composition and microstructure of ZnO nanorods. Given the size of ZnO nanorods, atomic force microscopy (AFM) is a suitable method for manipulating individual ZnO nanorods and measuring their elastic properties. However, the effects of oxygen plasma on the mechanical properties of ZnO nanorods has not been systematically studied using a precise measurement technique. When ZnO nanorods are exposed to oxygen plasma, the charge carrier concentration decreases and the piezoelectric output voltage consequently increases. The power generation in piezoelectric nanogenerators based on ZnO nanorods can be improved via several approaches, including an oxygen plasma treatment. ZnO in the form of nanorods has been studied intensively for application in self-powering devices. Zinc oxide (ZnO) simultaneously exhibits semiconducting and piezoelectric properties.

0 kommentar(er)

0 kommentar(er)